LOBP-Consulting GmbH

Phone +49 4102 821211 | info@lobp.com

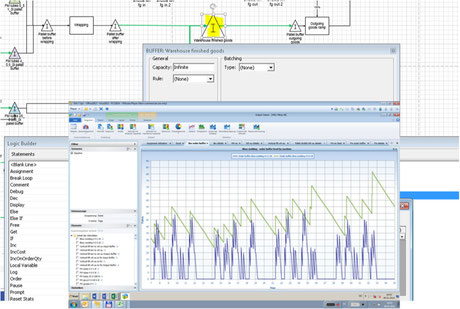

Simulation & analysis technology

To minimize costs, increase throughput, improve productivity, manage inventory or meet customer demand, simulation and analysis technology provides a cost effective, high value solution to

achieve your objectives. With the recent advancement in computer technology, computing speed has increased significantly, leading to an improved usage environment.

Examples of Simulation and Analysis Technologies

Regular Process Simulation

This technology calculates material flow balances based on production batches, orders for production, filling, warehousing or blow molding, which constitute the basis of plant design, and offers engineering data necessary for equipment and piping design.

Dynamic Simulation

Turbulent and volatile markets have become the norm as life-cycles shorten and global economics and competitive forces lead to additional uncertainty in the lubricants business.

The risk in grease, lubricants blending, filling and packaging plants and attached to lengthy and slow-moving logistics has become unsustainable, forcing the designers to look again at how their

process/material flow are structured and managed. It is extremely important to recognize plant behavior when the plant is loaded with volatile production orders and to reflect the recognized

behavior in the plant design. Today, it is possible to create a dynamic model of plant, logistic and study it from various aspects.